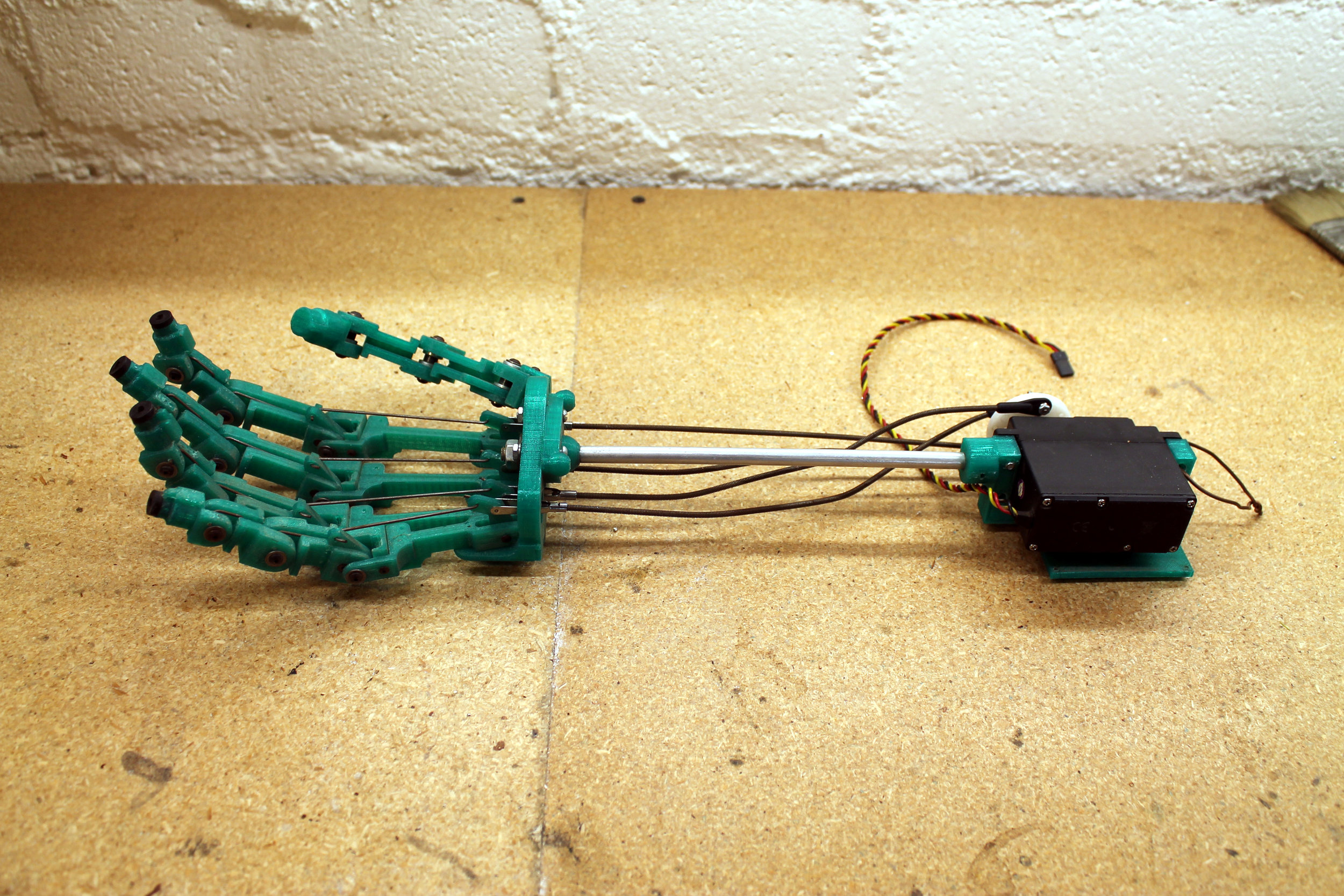

My First 3d Printed Project: The Crawling Terminator Hand

/I was always interested in 3d printing for the purpose making functional mechanisms. I still had all my mechanical drawings from that previously mentioned Terminator project and decided to 3d print an articulated robot hand. Not just any robot hand, but something capable of dragging itself along under its own power. I wanted to see what 3d printed mechanisms could do.

The Terminator hand design was based upon the T-800 Endoskeleton Arm that used to be available from Sideshow Collectibles. That model was apparently molded directly from a working terminator arm made at Stan Winston Studios for use in the movies. It had the screw heads and accommodations for finger linkages already laid out and the dimensions were exactly what they needed to be to recreate the functional mechanism.

The mechanisms for the T-800 hands were originally fabricated using traditional machining techniques ( of course). This meant there were plenty of places to grip the parts in a vise or a 4 jaw chuck for the machining process. These features translated well to the technology of FDM 3d printing, where it is desirable to have flat surfaces to attach to the print bed.

Finger Parts being Grown on 3d Printer

Finished Parts